SMT first article inspection system-JCX860

$18,840.00

This price is for delivery to Shenzhen Port(EXW, FCA, CPT), If free shipping is required, please contact customer service before purchasing: service@smtfuture.com

Main functions of jcx-860:

1. Save personnel: change from 2 people to 1 person.

2. Improve efficiency: the speed of first article inspection is increased by more than twice, and there is no need to switch the measuring range and compare the measured values manually.

3. Reliability: the SMT intelligent first article detector jcx-860 perfectly checks the BOM, coordinates and drawings, displays the detection situation in real time, avoids missing inspection, and can automatically determine the qualified value of the component value according to the error range, and conveniently check the multi paste, wrong material, polarity and packaging; The traditional way completely depends on personnel, which is easy to make mistakes.

4. Visibility: SMT intelligent first article detector jcx-860 system enlarges the physical object dozens of times for PCB tag number diagram or scanned PCB image, with high definition and easy identification and positioning; In the traditional way, operators need to check BOM, component location diagram and non LCR backlight silk screen printing, which is easy to visual fatigue and easy to make mistakes.

5. Traceability: automatically generate the first article inspection report and restore the inspection scene.

6. More accurate: use high-precision LCR tester instead of multimeter.

7. Process drawing: SMT first article process drawing can be generated at the same time, which is convenient for quality control or maintenance personnel.

8. Scalability: the software supports stand-alone version and network.

Description

Detailed description

With only 30 minutes to wait for the smt-860 automatic testing machine, which can automatically determine the production direction of the smt-860 automatic testing machine. SMT first article tester can automatically input measurement data through intelligent integration of CAD coordinates, BOM list and first article PCB scanning drawing. Manual data input is not allowed to eliminate human errors and omissions. The first article inspection of SMT production line is simplified and the inspection efficiency is improved by 80%.

Advantages

Improve production efficiency, reduce labor cost, automatically judge test results, improve product quality, have traceability and strict process specification

Scan the first PCB of SMT patch to be detected, obtain the scanned picture of PCB in kind by smart frame, and import the BOM list and PCB component patch coordinates. The software performs intelligent synthesis and intelligent global coordinate calibration on PCB pictures, BOMs and coordinates, so that the component coordinates, BOMs and the positions of physical components in the pictures correspond one by one. By navigating the measurement target, the LCR reads the data, automatically corresponds to the corresponding position, and automatically judges the detection results. Eliminate false test and missing test, and automatically generate test reports and store them in the database.

Z large scanning range: 320mm × 420mm

Z small detection element: 0201

Z large element height: 26mm

Input voltage: ac200-230v0 9kAV

Working characteristics

1. Intelligent matching of BOM, CAD and image

One click PCB scanning and image reading;

Edit BOM and CAD humanized and match coordinates conveniently;

2. Diversified inquiry functions

Humanized selection of the next detection element;

Various personalized query functions;

Fast navigation and measurement target;

3. Intelligent auxiliary detection function

The smart frame obtains the PCB scanning area;

Multiple windows on the computer screen to display the information of the components to be tested synchronously in real time;

Intelligently calibrate the coordinate offset to perfectly solve the coordinate matching of non silk screen PCB;

LCR automatic reading and automatic gear adjustment function;

4. Standardize the production process and improve the traceability of quality management

Leak proof and error proof functions;

Recheck function;

Automatically judge the measurement results to avoid human errors;

The complete test report is stored in the database;

Main highlights of jcx-860

1. PCBA HD graphics can be obtained by using PDF tag map or scanning equipment.

2. The component detection sequence can be automatically switched by software or manually controlled, with advanced automatic optimization algorithm.

3. It can be tested by component category or by specifying a certain specification of components.

4. The software automatically switches gears and corresponding frequencies.

5. Fully automatic judgment of test results: pass / fail. After passing the test, the software automatically jumps to the next part without manual key pressing, and gives the corresponding prompt tone.

6. The empty paste position will be marked with “fork” automatically, and it will be skipped automatically during the test.

7. The statistical information such as detection number, missed measurement number, pass number and fail number are displayed in real time to eliminate the phenomenon of missed measurement.

8. More convenient manual judgment and defect cause recording.

9. More convenient way to find and locate components.

10. Fully automatic acquisition of component test parameters.

11. SMT first article process drawing can be generated at the same time, which is convenient for quality control or maintenance personnel.

12. Support the import of double-sided coordinates, select only one side for detection, and support the detection of different versions of the same product without redoing the program.

13. More flexible parameter definition method supports multi style BOM of incoming processing enterprises, and can customize and read specific BOM format for customers

14. Test data will be saved automatically to prevent stalling or accidental power failure.

15. It can automatically simulate the action of manually ticking the tested components in the BOM, so that the tested components and unmeasured components can be seen at a glance and many parts can be prevented from being dazed.

16. Automatic voice broadcasting, such as tag number, package, component value, etc

Email: service@smtfuture.com

Additional Information

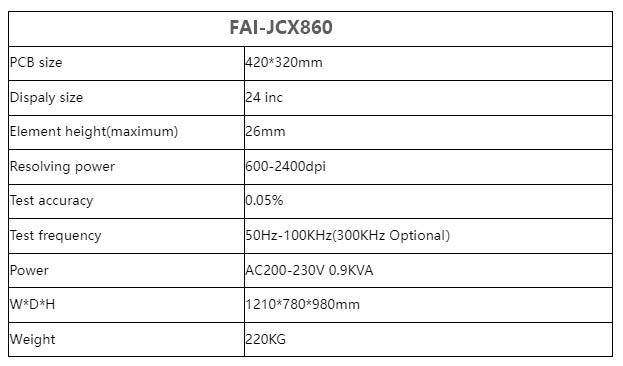

| Weight | 220 kg |

|---|---|

| Dimensions | 1210 × 780 × 980 mm |