SMT first article inspection system-JCX830

$4,710.00

This price is for delivery to Shenzhen Port(EXW, FCA, CPT), If free shipping is required, please contact customer service before purchasing: service@smtfuture.com

Advantages:

- Save half the manpower: the first tester can be easily competent.

- Save half inspection time: fast, effectively reduce production line standby time.

- Effectively improve quality: eliminate human error, precision, do not miss the test.

- Automatic report generation: automatic report generation after test.

- Easy to operate: import BOM、CAD coordinates, images to generate programs.

- Protect customer investment: product upgrade, improve product performance and function to protect customer investment.

Function description:

1. The interface supports Chinese, British and Japanese languages, military industrial control host, Windows 7、64 bit system, I5 processor 500 G solid state hard disk 8 G running memory 24 inch display.

2. The software automatically recognizes and processes BOM information, supports the comparison of two BOM differences, automatically recognizes patch coordinate files, automatically optimizes paths, automatically determines test results (voice prompts), saves data in real time, and automatically generates test reports. Reduce efficiency, automatic prevention, improve quality, quality traceability.

3. High precision custom JCX860LCR test bridge :0.05% basic measurement accuracy, customized SMT first special test fixture.

Description

Detailed description

Equipment introduction

1) System introduction

SMT first article inspection system-JCX830 is a new scheme for reducing personnel and increasing efficiency in SMT first article confirmation. It automatically generates inspection procedures by integrating BOM, CAD and drawings, quickly and accurately detects components one by one, and automatically determines the results. Using this system, only one person is required to operate independently, and the inspection time can be reduced by more than 50%. More importantly, it reduces human errors and improves the accuracy and traceability of first article inspection, Ensure the quality of production.

2) Equipment principle

Jcx-830 is a special equipment for SMT first board inspection. Its principle is to import the BOM, CAD files and drawings of the first board into the system, and the system will automatically synthesize the inspection program. Employees will inspect the first piece one by one according to the inspection program automatically generated by the system, and the system will record the measured values and automatically determine the results.

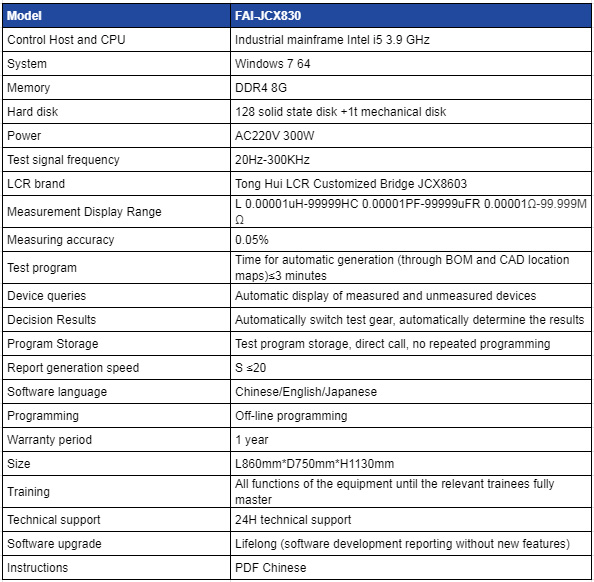

Technical parameters

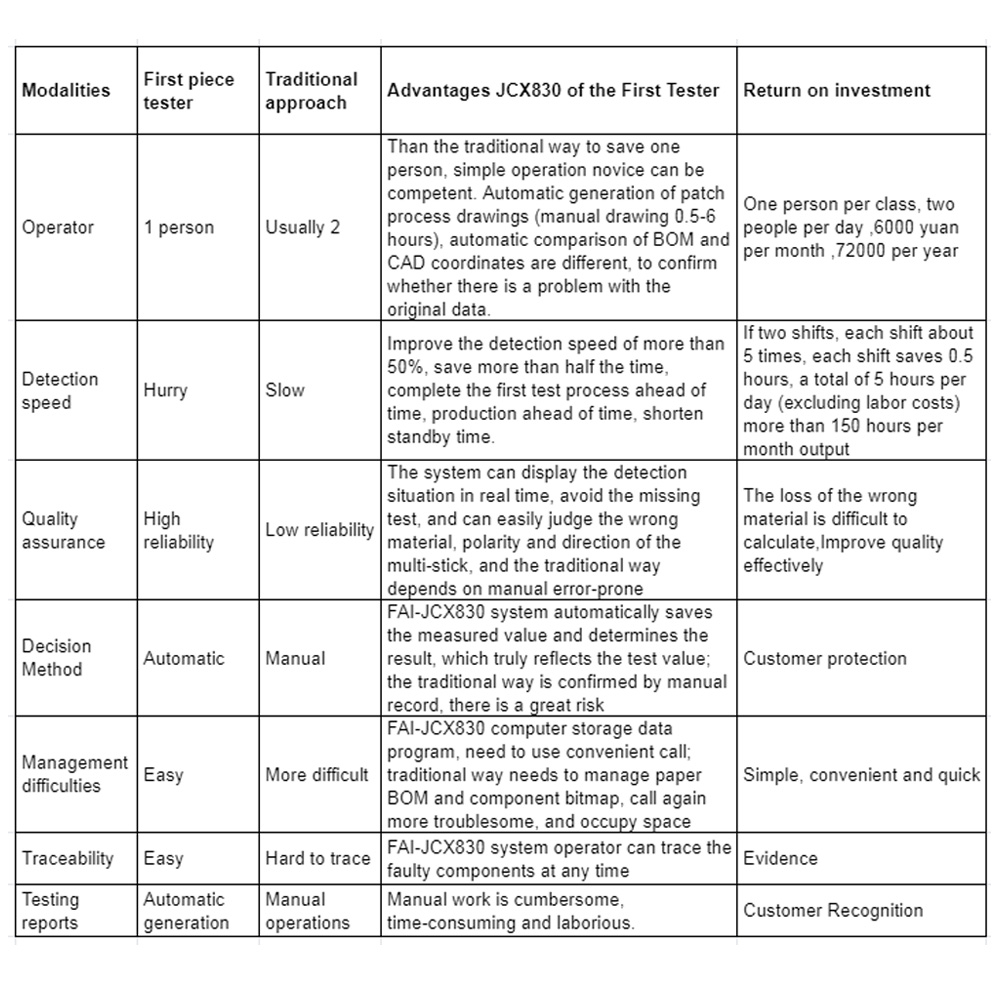

SMT Comparison of the FAI-JCX830 of the First Test Instrument and the Traditional Manual Test Method

| Product model | Number of components | Test methodology | Number of persons tested | Test time |

| A | 200 | Manual | 2 | 30-50 minutes |

| First piece tester | 1 | About 15 minutes | ||

| B | 500 | Manual | 2 | 90-120 minutes |

| First piece tester | 1 | About 30 minutes |

Characteristics and advantages of equipment

SMT first article tester

1. Simple operation – when testing, the operator takes the probe in one hand to measure, and the system will automatically record the data, which only needs one person to operate (while the traditional complex circuit board usually needs the cooperation of two people)

2. Save time – practice has proved that the working efficiency of jcx-830 first board detection system can be improved by about 50%, which can greatly save valuable time for SMT.

3. Correctness of values – the original BOM and CAD files of the customer are used to directly import into the system and generate the inspection program to ensure the correctness of the first article inspection data.

4. Truly reflect the measured value – the data read by LCR is automatically recorded in the system, and the report can be generated automatically, which can be displayed intuitively and can not be modified manually.

5. Avoid missing measurement – during detection, the system will dynamically display the number of measured and unmeasured components. If there is missing measurement, it is clear at a glance.

6. It can detect the situation of more pasting and less pasting – it is convenient to confirm the position of skip (not pasting parts). If parts are found in such positions, it is abnormal. The clear and enlarged picture will enable the operator to find their position quickly and accurately.

7. Simple and convenient program management – the detection program is saved by the computer and easy to call. (the paper materials of BOM and location map need to be kept in the traditional way).

8. Sample function – after the test is OK, it can be saved as a sample. When the same model is tested next time, it can be called out for comparison and judgment, so as to make the test work more rapid and efficient.

9. Easy to find components – the system has a search function, and employees can quickly query and locate components according to tag number, name or other information.

10. Automatic generation of perfect test report – complete test report can be generated automatically after testing, which is convenient for tracing the source; At the same time, it also saves the tedious and time of making reports; The test report is read-only in Excel document, which truly reflects the actual situation and avoids human modification and error.

In terms of detection efficiency and quality, jcx-830 is greatly improved compared with traditional methods.

Additional Information

| Weight | 96 kg |

|---|---|

| Dimensions | 860 × 750 × 1130 mm |