SMT first article inspection system-JCX820

SMT first article inspection system-JCX820 is a new scheme for reducing personnel and increasing efficiency in SMT first article confirmation. It automatically generates inspection procedures by integrating BOM, CAD and drawings, quickly and accurately detects components one by one, and automatically determines the results. Using this system, only one person is required to operate independently, and the inspection time can be reduced by more than 50%. More importantly, it reduces human errors and improves the accuracy and traceability of first article inspection, Ensure the quality of production.

Description

Detailed description

Design concept

Nowadays, SMT electronic factories have more and more models, small batches and frequent line changes, which makes the task of first article inspection more and more important. The traditional SMT first article inspection method is not only a waste of manpower and low efficiency, but also the whole inspection process is lack of control and quality can not be guaranteed.

SMT intelligent detection system – jcx820, through the intelligent integration of CAD coordinates, BOM list and first piece PCB screen printing, the system automatically enters the measurement data, does not allow manual data entry, and eliminates human errors and omissions, so as to simplify the first piece inspection of SMT production line and improve the inspection efficiency by 80%.

Working mode

Import BOM and PCB component patch coordinates. The software performs intelligent synthesis and intelligent global coordinate calibration on the drawing (silk screen drawing), BOM and coordinates, so that the component coordinates and BOM correspond to the positions of physical components in the picture one by one. By navigating the measurement target, the LCR reads the data, automatically corresponds to the corresponding position, and automatically judges the detection results. Eliminate false test and missing test, and automatically generate test reports and store them in the database.

Product advantages

1. Save half manpower: the traditional SMT first article inspection usually requires two operators. Using jcx-820 first article detector, one person can be easily competent.

2. Save half the inspection time: hundreds of customers verify that using jcx-820 first article tester and single person operation can save 50% – 80% of the first article inspection time and effectively reduce the waiting time of the production line.

3. Effectively improve the quality: using jcx-820 first article detector, the whole testing link can be controlled completely, so as to eliminate the errors that are considered, and there will be no missed inspection and misjudgment, and the data can be traced at any time.

SMT smart first product tester

4. Auto generate report: after detection, the detection report can be generated automatically. Report the real reaction test process, which can be archived or sent to customers.

5. The operation is very simple: the system has a friendly interface, automatic value reading, automatic judgment and prompt tone. The operator can learn it on the same day and be proficient in operation within 3 days.

6. Traceability: automatically generate the first article inspection report and restore the inspection scene.

7. Protect customer investment: products are upgraded irregularly to improve new capabilities and functions of products and protect customer investment.

Function highlights

1. Intelligent matching of BOM, CAD and image

Edit BOM and CAD humanized and match coordinates conveniently;

2. Diversified inquiry functions

Humanized selection of the next detection element;

Various personalized query functions;

Fast navigation and measurement target;

3. Intelligent auxiliary detection function

Multiple windows on the computer screen to display the information of the components to be tested synchronously in real time;

LCR automatic reading and automatic gear adjustment function;

4. Standardize the production process and improve the traceability of quality management

Leak proof and error proof functions;

Recheck function;

Automatically judge the measurement results to avoid human errors;

The complete test report is stored in the database;

Email: service@smtfuture.com

Additional Information

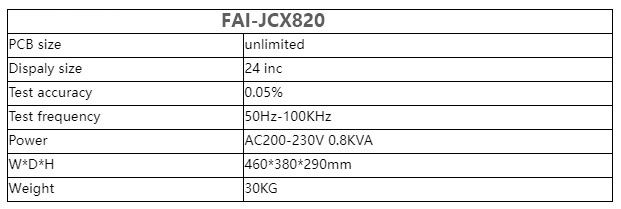

| Weight | 30 kg |

|---|---|

| Dimensions | 460 × 380 × 290 mm |